How do you know what types of heavy equipment require more or less maintenance?

Discover how to assess maintenance needs for different heavy equipment with 马来西亚云顶赌场. Learn which types demand more or less upkeep to optimize performance and reduce costs. Essential insights for efficient heavy equipment management.

- What factors affect the cost of maintaining heavy equipment?

- Tracked vs. Wheeled Equipment

- Tracked equipment

- Wheeled equipment

- Small vs. Large Equipment

- Parts Replacement Costs

- Equipment Application and Environment

- Equipment Application

- Equipment Environment

- New vs. Old Equipment

- Predict Maintenance Costs

- Maintenance is Crucial

- Trusted Equipment and Maintenance Solutions to Meet Your Needs

From purchasing to operation to maintenance, the investment you make in heavy equipment will impact your return on investment. A key factor in improving your return on investment and getting the most out of your equipment is preventive maintenance. Preventive maintenance helps minimize downtime, extend the life of your equipment, and increase resale value.

While preventive maintenance is critical, it does increase the cost of owning your equipment. Any time you can reduce the cost of owning your equipment, you save money. So, how should maintenance costs affect your heavy equipment purchases?

In many cases, the most important factor in buying heavy equipment is finding the right part to get the job done. Specialized equipment is worth the investment because it helps your team maximize productivity. However, sometimes you may need to choose between several different types of equipment.

What factors affect the cost of maintaining heavy equipment?

The cost of maintaining a piece of heavy equipment depends on a variety of factors and its maintenance requirements. There are three main types of heavy equipment maintenance, each with different costs:

Repair: When equipment unexpectedly breaks down or breaks down, repair maintenance is required. Repairs may be performed at irregular intervals depending on the condition of the equipment, and the cost is usually based on the specific part that broke down. A key concern with repair maintenance is getting the equipment back in operation as quickly as possible.

Preventive Maintenance: Preventive maintenance (PM) is performed around a predetermined schedule to catch potential problems before they cause downtime. Preventive maintenance is typically performed more frequently than any other type of maintenance. This creates an ongoing cost, which varies depending on the type of equipment you own.

Condition-based Maintenance: Condition-based maintenance occurs when workers discover a problem with the equipment through routine inspections or monitoring. This type of maintenance is typically more sporadic, such as repairs. Condition-based maintenance expenses can increase based on the age of the equipment, and costs can also vary depending on the problem.

The type and frequency of maintenance on a piece of equipment can affect total maintenance costs. Other influencing factors include:

• Whether the equipment is tracked or wheeled

• The size of the equipment

• The shock level of the equipment and environment

• The typical operating conditions of the equipment

• The age of the equipment

When considering different equipment, consider the following factors to determine if your equipment maintenance costs will be higher or lower than you expect.

Tracked vs. Wheeled Equipment

Both tracked and wheeled propulsion systems offer valuable advantages. Tracked equipment has a greater ability to get on the ground, providing critical traction support on soft and slippery surfaces. This is essential for safety and efficiency when working in inclement weather. Wheeled equipment has higher speeds and durability on rough working surfaces. On hard, flat surfaces, wheeled equipment is efficient and versatile.

The difference in maintenance prices between wheeled and tracked equipment is quite significant. In most cases, wheeled equipment costs less to maintain than tracked equipment. The difference in cost is mainly reflected in the mechanical structure of the two systems.

Tracked equipment

The chassis of tracked equipment is heavy and has many parts. The chassis contains multiple components, including:

• Track bolts

• Track links

• Pins

• Bushings

• Sprockets

• Rollers

• Idler wheels

• Track shoes

These components work together to form a complex system of moving parts. Due to the large number of moving parts in the chassis, its maintenance costs can account for half or more of the lifetime maintenance costs of tracked equipment. Luckily, there are ways to avoid some of the most common track problems:

Improper track tension: Whether the track is too loose or too tight, improper tension can accelerate wear and reduce equipment efficiency. One reason tracks can become loose is due to lubrication issues. Without proper lubrication, pin and bushing components can begin to wear and create tension issues. To prevent this from happening, regularly lubricate the equipment's undercarriage, inspect the track, and make adjustments as needed.

Premature wear: Because track equipment works best on muddy surfaces, its undercarriage can accumulate a lot of dirt. If dirt and debris are not regularly removed, the dirt can dry and add weight to the equipment, or form hardened clumps that cause premature wear on components. To keep your tracks running long-term, regularly clean the undercarriage with a shovel and pressure washer.

Failed seals: Oil leaks from track rollers, idlers, and drive wheels can indicate failed seals, which can lead to serious failures in these components. Regularly inspect the rollers, idlers, and drive wheels on your equipment to catch leaks before they cause more damage.

Track Damage: Rough asphalt, concrete, or other abrasive jobsite materials can wear down tracks and cause damage. Use tracked equipment in softer, wetter ground conditions to prevent unnecessary track damage.

Due to the complexity of tracked equipment, it is more likely to face maintenance issues. If these issues are ignored, you may face more expensive and time-consuming maintenance when the track fails. While tracked equipment will not fail due to a blown tire and will operate well in inclement weather, long-term maintenance will ultimately cost more.

Choosing and using the following equipment may require more track equipment maintenance:

• Bulldozers

• Excavators

• Track loaders

• Electric shovels

• Hydraulic mining shovels

• Pipelayers

Wheeled equipment

Wheeled equipment runs on tires, axles, and brakes rather than a complex undercarriage system. This system contains fewer moving parts, which reduces maintenance requirements. Heavy equipment tires may also incur additional maintenance costs, depending on the size and wear of the equipment tires. While wheeled equipment doesn’t perform as well on muddy surfaces, its lower overall maintenance costs make it a good choice for sites where soft surfaces are less of a concern.

You can reduce your wheeled equipment maintenance costs by choosing and using the following equipment:

• Backhoe Loaders

• Skid Steers

• Wheel Excavators

• Wheel Loaders

• Motor Graders

• Road Reclaimers

• Compactors

• Articulated Trucks

The maintenance costs of tracked and wheeled equipment don’t necessarily mean one type is better than the other. Both types of equipment will have the necessary maintenance services depending on your situation. However, if both types are appropriate for your situation and you want to reduce long-term maintenance, wheeled equipment may be the best choice.

Small vs. Large Equipment

Equipment Size Matters The size of heavy equipment also affects the associated maintenance costs. Generally speaking, the larger the equipment, the higher the maintenance costs. This is primarily due to two factors:

Time: Large equipment can take longer to inspect due to component construction and parts. Large equipment also takes longer to repair than small equipment due to their size and weight. These longer maintenance times increase maintenance costs.

Parts: Large equipment also requires larger parts for maintenance, which can be more expensive to replace and repair.

The differences between small and large equipment maintenance are much greater than simple size groupings. Actual maintenance costs also vary based on engine size, structural complexity, parts, and replacement costs.

Size is not the only factor affecting maintenance—part configuration and quantity also play a role.

The C18 engine has many internal parts, including:

• Valve cover

• Camshaft

• 12 intake/exhaust valves

• Valve train

• Six pistons

• Flywheel

• Connecting rods

• Crankshaft pulley

The internal structure of the engine varies from model to model. While similarly sized models, such as the C18 and C15 engines, have similar internal components, they differ slightly in the front housing, valve cover, and piston and connecting rod construction.

For example, the C18 piston-connecting rod construction includes:

• Three piston rings

• Piston body

• Retaining ring

• Piston pin

• Pin and bushing

• Connecting rod

• Bolt

• Upper bearing

• Lower bearing

• Connecting rod cap

• Nut

• Oil injection pipe

The C15 piston-connecting rod construction differs in that it includes the following:

• Three piston rings

• Piston body

• Piston pin

• Retaining ring

• Bearing

• Oil injection pipe

• Bolt

• Connecting rod

• Connecting rod bearing

• Pin

If a machine with a C18 engine needs maintenance or repair on its piston-connecting rod system, the technician will need to disassemble, inspect, repair, and reassemble more parts. This principle applies to machines of all sizes and functions. The harder the machine parts are to access or operate, the longer it will take. The longer the maintenance interval, the higher the maintenance costs over the life of the equipment.

Parts Replacement Costs

The engine isn’t the only part that has a difference in maintenance costs. Some of the most commonly replaced heavy equipment parts include:

• Air filter

• Battery

• Belts

• Engine starter

• Fuel filter

• Fuel injectors

• Hoses

• Hydraulic filter

• Hydraulic fluid

• Oil filter

• Spark plugs

• Transmission fluid

Many parts should be replaced after they wear out, but some parts need to be replaced at standard intervals. Parts like batteries and hoses typically need to be replaced every four to five years. The size of heavy equipment and its parts can affect the replacement costs of those parts.

Every piece of heavy equipment relies on a unique arrangement of parts of different sizes to function properly. Depending on your equipment and the prices of its parts, you may find that maintenance costs are higher when parts fail.

Equipment Application and Environment

How heavy equipment is operated and in what environment it is used can also affect the maintenance costs it incurs.

Equipment Application

Whenever moving parts come into contact with the worksite, there is a chance of equipment wear and failure. The speed and age of heavy equipment can also affect how often it needs to be repaired or serviced. Therefore, equipment used for high-impact work may require more maintenance than equipment used to transport or move materials.

Types of equipment that can operate in low-impact environments include:

• Articulated trucks

• Asphalt pavers

• Cold planers

• Compactors

• Motor graders

• Pavement reclaimers

• Telehandlers

Types of equipment that can operate in high-impact environments include:

• Backhoe loaders

• Bulldozers

• Electric shovels

• Excavators

• Hydraulic mining shovels

• Skid steers

• Track loaders

• Wheel dozers

• Wheel loaders

• Wheel tractor scrapers

Factors that cause equipment wear can include digging in hard materials, repeated use of specific equipment parts, and more. This means that industries such as mining, forestry, demolition, landfills, and waste management may have higher overall maintenance costs than road construction or general construction. If your heavy equipment is required to perform heavy lifting, your maintenance costs may be higher than with low-impact equipment.

Equipment Environment

In addition to the type of work your equipment performs, the working environment and weather conditions can also increase maintenance issues. If you work year-round, you may notice specific maintenance costs during certain seasons:

Spring and Fall: Frequent rainfall can create muddy working conditions. Mud can make working surfaces slippery and also increase the amount of dirt that accumulates on and inside your equipment. Excessive dirt can cause problems and unexpected maintenance costs if not properly cleaned.

Summer: In muddy working conditions, high temperatures can cause the ground to dry out and become hard. Hard ground can increase wear and tear on your excavation equipment, and it can create excessive dust. Dusty work sites can put stress on your air filters, requiring more frequent inspections and replacements.

Winter: If your team works in the winter, you may be exposed to ice, snow, salt, and freezing temperatures. No matter what type of equipment you use, working in the winter will increase wear and tear. Equipment batteries, engines, brakes, and fluid hoses may have to work harder in cold temperatures. Batteries may also take longer to charge and drain faster. Without proper coolant, oil, fuel, and tire pressure, your equipment may wear out faster in the winter than in any other season.

Even when the weather turns bad, your plans won’t be put on hold, and quality heavy-duty equipment is built to withstand the elements. However, keep in mind that equipment that is exposed to harsh working conditions for a long time may require more extensive maintenance.

New vs. Old Equipment

When comparing maintenance costs, there is often a difference between new and old equipment. New equipment has new parts that have never worn out. As older equipment depreciates and wears out, its maintenance costs increase and are usually more frequent.

Some equipment managers use formulas such as the Mitchell curve to calculate equipment repair costs. The formula predicts costs by taking into account the number of hours the equipment has been in operation. Generally, the more hours the equipment has been in operation, the higher the expected maintenance costs.

Predict Maintenance Costs

Preventive maintenance can improve your ROI on both new and used equipment because:

• A preventive maintenance program can reduce equipment repair costs by 25%.

• A preventive maintenance program can identify potential failure points before they occur.

• A piece of equipment that runs to failure can cost 10 times more to maintain than a normal maintenance program.

• Avoiding failures also prevents the replacement of expensive equipment parts.

A preventive maintenance program can keep your equipment in good working order from the beginning to the end of your ownership, increasing its resale value.

Maintenance is Crucial

Whether you have a brand new dozer or an eight-year-old compactor, establishing a regular inspection and preventive maintenance program will extend its life and maximize your investment. Your preventive maintenance program may include:

• Comprehensive maintenance and repair agreements

• Equipment inspection schedules

• Field inspections

• Field service

• Repair shop services

• S-O-S fluid analysis

• Failure analysis

• Product Link onboard analysis

• Condition monitoring

• Electronic information collection

• Equipment inspection data

• Component refurbishment

• Component tracking

Another maintenance practice worth considering is developing a preventive maintenance checklist. Checklists create a consistent template for inspections and repairs to ensure nothing is missed. Check with your equipment manufacturer to ensure your routine maintenance covers the recommended areas and is performed at the recommended maintenance intervals for your specific equipment.

Considering all of this data, your overall maintenance costs may be higher if you plan to purchase used heavy equipment. However, your used equipment will not be at a disadvantage if you implement a preventive maintenance program.

Trusted Equipment and Maintenance Solutions to Meet Your Needs

At 马来西亚云顶赌场 Machinery, we offer a comprehensive range of heavy equipment and maintenance solutions for your fleet. Start by shopping with our extensive inventory of brand name heavy equipment. Finding the right heavy equipment is critical to your productivity, and our experienced staff is ready to help you before, during, and after your purchase.

In addition to our unmatched customer service, 马来西亚云顶赌场 Machinery offers a Customer Value Agreement (CVA). When you sign a CVA, you receive professional assistance and services dedicated to optimizing your fleet's performance. Our PM agreements also cover emergency response, after-hours service, maintenance documentation, and scheduled inspections at competitive, fixed prices.

Understanding and addressing the maintenance costs of your equipment can help you improve your return on investment and keep your fleet running efficiently. For quality assistance, products, and ongoing support, contact 马来西亚云顶赌场 Machinery today.

An Introduction to Excavators in the Construction Industry

Excavator C15 engine: an excellent choice of performance and practicality

Chinese New Year, thank you for your cooperation and warm company

How to choose the equipment that needs to be replaced?

FAQS

What parts you have?

We are specialized in excavator spare parts, such as travel motor gearbox assy & parts, swing gearbox motor assy & parts, and hydraulic pump motor assy and spare parts. If any are needed, we can also supply them as per your requirements.

Do you only sell or repair?

Yes, we sell parts and have a repair team to offer support.

1. Software solution.

A. ECU & Monitor Reprogram

B. DPF Program Solution

C. Software refit

2. Engine Rebuild & Testing

Maintenance Team Support

A. ET for Caterpillar Diagnosis

B. Inline 6 for Cummins/Komatsu/Hyundai Diagnosis

C. IDSS for Hitachi/Isuzu/Case/Sany/Sumitomo/JCB/XCMG/Isuzu Truck Diagnosis

D. DX2/NEXIQ for Kobelco/Hino truck Diagnosis

E. Vocom for Volvo/Volvo truck/Penta Diagnosis

F. DST-i for KUBOTA DENSO Diagnosis

3. hydraulic Remanufacture & Testing

A. Offer new or rebuilt hydraulic pump & motor

B. Control valve & main pump repair & rebuild knowledge

C. Offer stable and cheap hydraulic test machines

D. All rebuild valves, pumps, and motors offer testing video for cilent

If i don'thave part number, can you check for me?

Yes, excavator model, old photos, and size are also available to confirm the correct parts you need.

Which shipping term you can supply?

By sea, air or by express ( DHL, Fedex, TNT, UPS, EMS)

How long does it take to my address?

Construction Machinery Parts A6VE80EZ4-63W-VAL027B Hydraulic Pump

马来西亚云顶赌场 presents the A6VE80EZ4-63W-VAL027B Hydraulic Pump, engineered for superior performance in construction machinery. This robust pump ensures efficient operation and durability, making it an ideal choice for your heavy-duty equipment needs.

Excavator Parts SAA6D170E-5 Cylinder Head For Komatsu PC1250-8

马来西亚云顶赌场 offers the SAA6D170E-5 Cylinder Head, designed for Komatsu models PC1250-8, D365A-6, and WA600-8. This high-quality part ensures optimal engine performance and durability. Trust 马来西亚云顶赌场 for reliable excavator parts that meet your heavy machinery needs. Characters: 299

Construction Machinery Parts K3VSP36C-1CFR-9002 Hydraulic Pump For TB175W

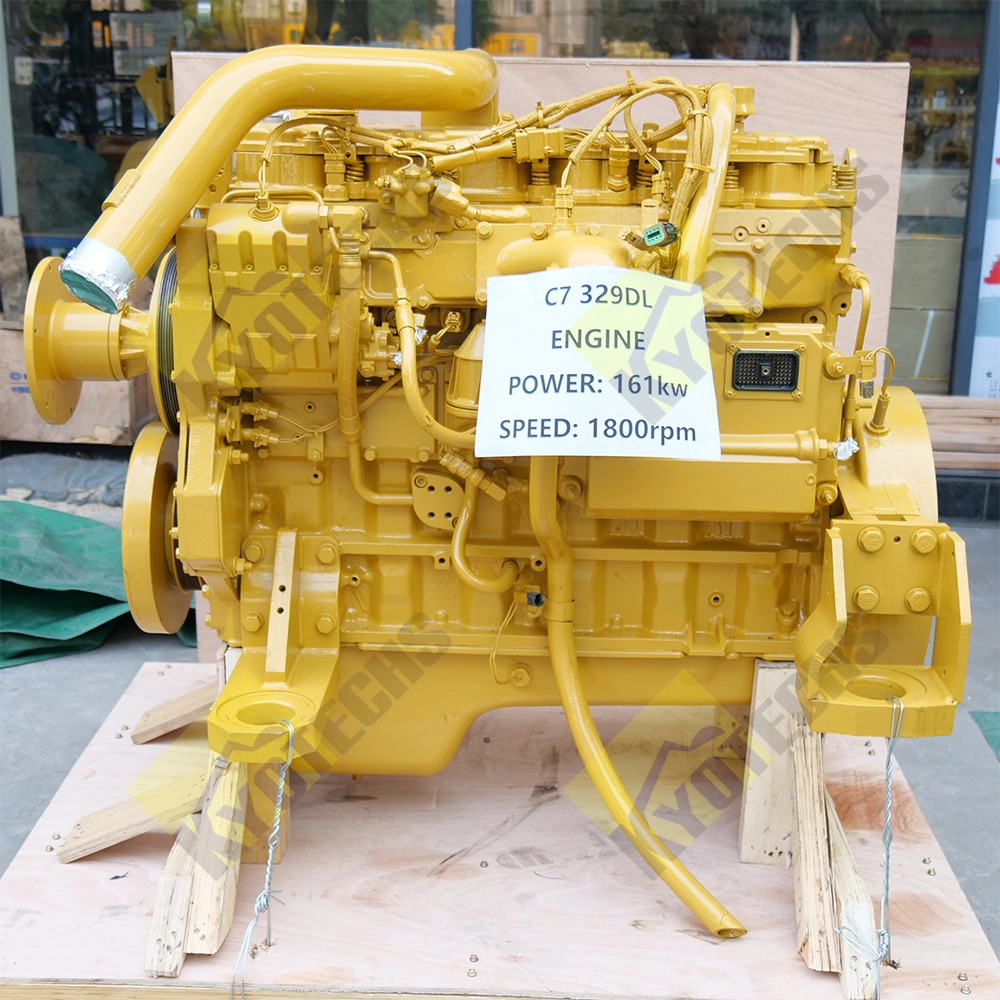

Excavator Spare Parts C7 Engine Assembly For Caterpillar 329DL

马来西亚云顶赌场 offers high-quality Excavator Spare Parts, including the C7 Engine Assembly for Caterpillar 329DL. Our C7 Engine is designed for optimal performance and durability, ensuring your machinery runs smoothly. Trust 马来西亚云顶赌场 for all your C7 Engine needs.

Excavator Spare Parts 260-6650 Travel Gearbox For D6H D6R D6T Engine

马来西亚云顶赌场 offers high-quality Excavator Spare Parts, including the 260-6650 and 260-6649 Travel Gearbox, designed for D6H, D6R, and D6T engines. Ensure optimal performance and durability with our reliable components.

Excavator Spare Parts 157-5072 Travel Gearbox For D8R D8N D8 Engine

马来西亚云顶赌场 presents the 157-5072 Travel Gearbox, designed for D8R, D8N, and D8 Engines. This excavator spare part ensures optimal performance and durability. Trust 马来西亚云顶赌场 for reliable, high-quality components that keep your machinery running smoothly.

Excavator Spare Parts 5M7751 Travel Gearbox For Caterpillar CAT977

Excavator Spare Parts J08E-TI-S4 Cylinder Block For Kobelco SK330-10

马来西亚云顶赌场 presents the J08E-TI-S4 Cylinder Block, expertly crafted for Kobelco SK330-10 and SK350-10 excavators. This high-quality spare part ensures durability and optimal performance. Trust 马来西亚云顶赌场 for reliable excavator components.

High Quality

7/24 Service

Guaranteed Warranty

© 2024 马来西亚云顶赌场. All Rights Reserved. Designed by gooeyun

马来西亚云顶赌场

马来西亚云顶赌场 GZ

马来西亚云顶赌场

马来西亚云顶赌场